Knowing whats in store

Read this before your PCs' next buying spree

by Dave Rosene

In a scenario I was DMing recently, one

of the characters strolled into the local

blacksmith shop to have a little repair work

done. To his surprise, he became the object

of a seemingly unprovoked attack by the

owner of the establishment. Luckily for

him, his opponent was not very bright and

he was able to escape in one piece. Luckily

for me, he did not decide to stand his

ground and fight with whatever was available.

I had little idea of what was inside the

shop other than a forge, a hammer and an

anvil. To avoid being caught in a similar

situation in the future, I did some research

on four kinds of shops likely to be frequented

by adventurers. Before examining

any individual establishments, however, we

should first go over a few points that may be

so obvious that they are overlooked during

the construction and stocking of a workshop

or store.

Any business requires a certain population

from which to draw its clientele. Those

customers must also be willing and able to

pay for the service the craftsman is offering.

There is the possibility of exporting, but not

always at prices competitive with those of

local craftsmen. As a rule (to which there

are always exceptions), shops located in

larger centers of population will have a

greater stock on hand, will produce higherquality

goods, and will tend to be more

specialized. In cities and sometimes even on

a regional basis, craft guilds maintain certain

quality standards and price levels. A

guild member found guilty of either manufacturing

substandard products or of overor

under-pricing could be stripped of his

guild membership. He would then be unable

to practice his craft within the area

encompassed by that guild without risking

the guild?s retaliation.

Most shops have some features in common.

If the shop is actually a structure, and

not a booth in a bazaar (a possibility not to

be overlooked), there will be items found in

any household: lamps, candles, oil, a sharpening

stone, rags, etc. Some material components

for spells may also be found in

places other than those specializing in such

items. A craftsman may unknowingly have

a much-needed component on hand which

can be acquired at little or no expense.

However, the craftsman?s workshop is not

a supermarket. If a smith caters to the

farmers in his area, he is not likely to carry

a large selection of swords. Near a castle a

smithy would be occupied with the manufacture

and repair of weapons or hardware

for the castle. Wealthy residents of a city

would demand ornate items that were less

utilitarian.

All but the richest craftsmen live behind,

above, or at best next door to their shops.

This is partly a matter of convenience, since

they often put in long hours and usually

work six days a week. Some or all of their

apprentices also live either in the shop or in

their master's home. On the whole, the

craftsman is a hard-working, respected

member of the community.

Remember, the existence and features of

any business must be dictated by the economic,

political and cultural environment in

order to maintain a believable campaign. In

the following sections we will browse four

shops, seeing them through the eyes of an

elven adventurer named Retgar. As we

travel from one shop to another, put yourself

alongside Retgar. Take in the atmosphere.

What do you see, hear, smell, and

feel? Keep these impressions in mind when

designing shops of your own. Following

each description is a short passage listing

accessory items that are typically found in

that kind of shop. (Keep in mind, though,

that not every shop will contain every item

listed.) Items denoted by an "S" can be

used as material components for spells. It

should be possible for an adventurer, stripped

of virtually all his wealth and possessions,

to reoutfit himself in a rudimentary

fashion by visiting shops such as these.

The anvil's ring

The Sun had not yet set as Retgar

reached the last ridge. Clinging to the base

of the foothills was the harbor city of Stonepoint.

Here he would find a smith to put a

new edge on his sword. But he decided that

the task could wait until morning, since he

had no desire to spend the night in a city

controlled by the overlord Zagus, who had

put a price-on Retgar's head.

At sunrise the next morning, Retgar

entered the dusty, winding streets. He fol

lowed the ringing of iron on iron until his

eyes picked out a weathered wood-frame

building at the far end of the street, adorned

with a faded sign in the shape of an anvil.

Smoke drifted up from the rough stone

chimney and settled around the shop. His

horse snorted at the smell of burning charcoal

as they reached the open double doors.

Sunlight streamed past them, quickly losing

its intensity in the hazy interior. Each strike

of the hammer bounced tiny bits of fiery

metal off the heavy leather apron worn by

the muscular smith. Retgar hailed him

during a momentary lapse in the rhythmic

clanging on the anvil and showed him his

badly notched sword. The smith examined

the blade, quickly determining that a new

edge was needed, and slid it into the hot

coals of the forge.

"We have few enough of you elves in

town. So I?m sure you?re not from these

parts. What news have you from lands

beyond?? As Retgar recounted some recent

events of which he had knowledge, he let his

eyes become accustomed to the dim light in

the room and examined his surroundings.

Opposite the door was a stone forge in

which charcoal glowed like a red sunset.

Through an open back door a young boy

entered carrying a bucket of charcoal he

had taken from a pile visible just outside.

He added a shovelful to the forge, carefully

arranging it with a long poker. Once satislied,

he pulled down on the handle of the

leather bellows, sending sparks dancing up

the chimney. Retgar felt the sweat beading

on his forehead as the smith interruped the

elf's discourse.

?Wesson, do not make it breathe as a

dragon or you will destroy the temper.?

While the smith explained the boy?s mistake,

Retgar leaned against the heavy

planked workbench and surveyed the implements

scattered across the surface. There

were punches and chisels of various sizes

and swages to mold the iron into shapes

such as rods and spikes. The square shaft

on the base of a swage was made to fit into

a square hole in the face of the anvil. As the

hot iron was held on the swage, it was hammered

into whatever shape was cut into the

surface. What?s the name of that hole in the

anvil, thought Retgar. . . . Of course ? a

hardie hole. And somewhere there had to be

a wide chisel with a square shank. The

chisel, or hardie, was inverted with its

handle in the hole. Then, heated iron was

cut by laying it across the upturned edge

and striking it with a hammer.

And there was certainly no shortage of

hammers in the shop. Nearly two dozen,

each weighing anywhere from a couple of

pounds to over thirty pounds, lay on and

around the workbench. Several of these

were unusual in that the handles were more

crude; the heads were flatter and not as well

balanced. One of them, lying next to the

hardie (chisel) that he had located, had a

corrugated face. This was not a hammer

but a fuller. It was struck with a hammer to

help flatten a piece of metal. The other

?hammers? were called flatters and were

used in much the same way. Retgar lifted

one of the flatters. Noting that it had a

concave face, he looked about for the armorer

?s anvil with which this was used. He

spotted the large, convex-faced anvil across

the room. A loud hissing brought his attention

back to the smith, who had just placed

a piece of hot metal into a half-barrel filled

with brine. This slack tub was used to cool

and temper the metal that was being

worked.

"Excuse the interruption. You were saying

something of the trouble Duke Earlin

was having with his half-brother," said the

smith.

As Retgar resumed his monologue, the

smith's hammer started clanging on the

anvil again, this time to put a new edge on

Retgar's sword. As the elf talked between

hammer-blows, he wandered across the

rough stone floor and poked about in a

rusting pile of broken weapons and farm

tools. From these, the resourceful smith

would craft new items. No one would have

guessed that the tools and weapons hanging

on the wall had once been pieces of scrap

from this pile.

Retgar finished his discourse at about the

same time as the refurbished sword made its

final dip in the slack tub. The elf examined

the blade?s new edge, noting that it would

need an hour or so with the sharpening

stone, and returned the sword to the sheath

at his side. As he paid the smith for his

services, Retgar decided that his purse was

much too light for his future needs. Perhaps

he would make a stop at the silversmith?s

shop before he left town.

Any small town would have its blacksmith

shop. If two or more shops are

present in a large town, each of them would

probably specialize in some aspect(s) of

smith work. These special occupations

include farrier (horses), wireworker (chainmail),

cutler (edged implements), and armorer

(only a few of whom are also able to

make barding).

Items of interest for game purposes:

charcoal (S), hammer (½ to 40 lbs.; depending

on weight, some may be usable as

warhammers at -1) long tongs (adds three

feet to reach), chisel (useful on locks in lieu

of thief), anvil (50 to 200 lbs. weight),

shovel, hole punch, file, sharpening stone,

any fabricated items in stock (90% of items

in scrap pile are useless), small pieces of

iron (S), soot (S), powdered iron (S), powdered

brass (only if the smith is specialized

in ornate work; S), small nails (S), sheet

iron (S), iron filings (S), pieces of steel (S),

brazier (used as a portable forge in a market;

S), and pieces of tin (S).

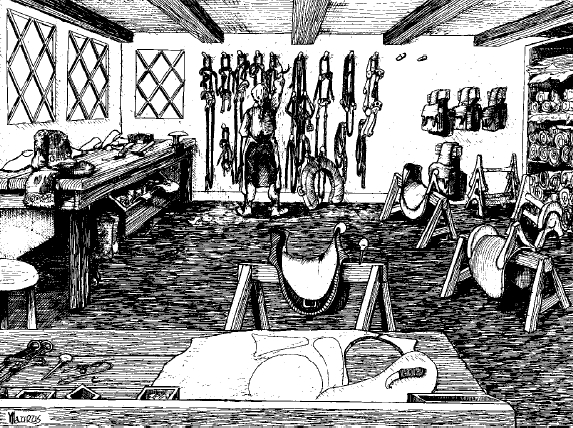

Bent for leather

The wooden, saddle-shaped sign that

hung above the door to the two-story woodframe

building indicated even to the illiterate

that this was a saddle shop. For Retgar,

the sign was unnecessary; from three doors

away he had been beckoned by the smell of

freshly cut leather. He stood in the open

doorway for a moment, taking in the

aroma. The shop was well lighted from the

many windows on all four walls of the spacious

room. To the left of the door stood a

large worktable. Here an apprentice was

using a curved knife to cut out the pieces of

a saddle previously marked on the leather.

There were knives, hammers and charcoal

pencils along the back of the bench as well

as half a dozen small bins. These contained

rings, buckles and rivets needed for saddles

and harnesses. Another young man at the

far end of the bench was stitching a ring

onto a bridle.

In the center of the hard-packed earthen

floor an older man bent over a saddle that

was resting on a wooden sawhorse. The

man, whom Retgar assumed to be the

master of the shop, was fastening a silver

buckle on the elaborate saddle. More saddles

in various stages of completion were

stacked on other sawhorses. Along the back

wall hung bridles, harnesses, and other tack

as well as saddlebags. In one of the far

corners were large shelves well-stocked with

uncut pieces of leather. A neat pile of

wooden saddletrees used as the framework

for saddles was on the floor beside the

shelves.

Retgar selected the largest set of saddlebags

he could see and slung them over his

shoulder. Turning, he noticed a worktable at

one end of the room. It was not until Retgar

took an interest in this worktable that

the saddler approached him.

?I can-see that you appreciate good

craftsmanship,? said the softspoken man as

Retgar picked up one of the boots on the

table. The inside was lined with doeskin.

The outside had an intricate design tooled

just below the rabbitskin that formed the

upper edge. ?The saddles I make to earn a

living. These I make for the pleasure it

gives me.?

Spread out on the table were knives,

needles, heavy linen thread, beeswax and a

small hammer, all laid within easy reach of

the lasting jack mounted to the workbench.

A little wooden box on the back of the

bench held tiny nails that were used to

fasten heels on boots. To hold the pieces of

other shoes together, linen thread or leather

strips were used.

Across the back of the bench were half a

dozen wooden foot molds in various sizes. If

you didn?t have the money for custom-fitted

shoes (and most people did not), then the

smallest of these sizes that fit comfortably

would have to do. Small pieces of soft

leather, rabbitskin, doeskin, and fleece were

kept in a bin below the bench to be used for

linings in boots and shoes.

Trying on a good-looking pair of boots,

Retgar was pleased to find that they fit.

After paying for his purchases, he slid his

old boots into the saddlebags and tossed

them up behind his saddle. Now, it was on

to replenish his nearly empty purse.

Leather workers in a city will be specialized

as saddlers, harnessmakers, bootmakers,

armorers, and cobblers. Small towns

will probably not have a leather worker or

will share one with a neighboring village.

Items of interest for game purposes:

lasting jack (small anvil weighing about live

lbs.), leather, skins, finished leather goods,

hammers (too small to be effective weapons),

hole punches, knives (most are usable

as a dagger at -1), rivets, small nails (particularly

treacherous to barefoot opponents;

S), metal rings and buckles, beeswax (adds

body to ointments), fish oils (or other oils

for waterproofing, also good as a base for

ointments and as a lubricant), needles (S)

and heavy thread (emergency first aid),

metal studs (many uses, mainly for studded

leather armor).

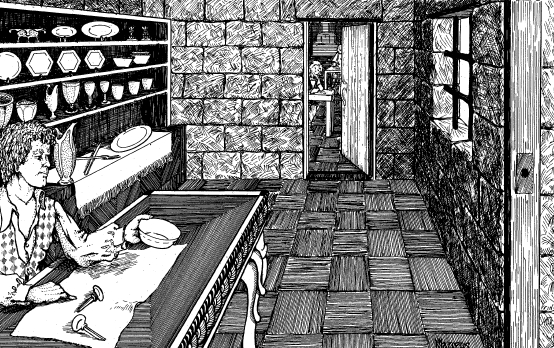

The silver chalice

Retgar had no difficulty finding the silversmith

?s shop. The two-story building was

constructed of grey cut stone. In the wall

facing the street was a single barred window

that could be shuttered and an iron-bound

oak door. Over the door hung a silvercolored

sign shaped like a goblet at the base

of which was printed, ?The Silver Chalice.?

The mark and initials on the sign were

identical to those on the base of the chalice

he carried in his pack. Retgar stepped from

the busy street and opened the heavy

wooden door.

Inside was a small, tidy room sparsely

furnished to display the items for sale.

Across the back wall were shelves lined with

cups, candlesticks, pitchers, vases, bowls,

platters, and various utensils. Most of the

items were made of silver, although a few

were gold or had gilded edges. A finely

crafted wooden table stood in front of the

shelves. At the table sat a young man etching

a design on a bowl. Retgar showed him

the chalice he had brought and was directed

through a door in the side wall.

The pleasant coolness of the front room

disappeared as soon as Retgar entered the

workshop, which seemed to take up the rest

of the building. Sunlight shone through the

barred windows, forming banded patterns

of light on the flagstone floor. Despite the

open windows, the room was uncomfortably

warm and smelled of hot metal. The source

of the heat was a small forge or furnace with

an open hearth next to it. Both were attached

to a bellows on which a young boy

pulled in a slow, even rhythm. A tarnished

metal hood channeled the smoke from the

open hearth into the brick chimney. The

furnace was also made of brick and had cast

iron doors. A tall man sweating heavily took

an urn from the furnace with a pair of longhandled

tongs and placed it on a grate

under the metal hood. He then slid another

urn into the furnace and closed the door.

With a long-handled ladle he dipped the

hot, shimmering liquid from the first crock

and poured it into a wooden mold which

was set on the workbench behind him.

The workbench was one of many, each of

which had a lit oil lamp suspended over it.

All of the benches were cluttered with tools.

There were nearly a dozen men of various

ages etching, engraving or hammering

designs into articles made of silver. The

noise of this activity was exceeded only by

the din of the blacksmith?s hammer and the

hawkers in the bazaar. Over the noise Retgar

heard a deep voice ask, ?Can I be of

some assistance?? The question came from

a slightly plump middle-aged man seated at

a workbench at the far side of the room. He

appeared to be the man in charge of the

numerous artisans.

Retgar wove his way between the tables

and workers. As he reached the master?s

table, the silversmith was dipping the goblet

he had been engraving into a weak solution

of sulfuric acid or ?pickle? to give it a final

cleaning. The goblet had the same hallmark

and initials on the base as the chalice that

Retgar unwrapped and set before his host.

The almost imperceptible twinkle in the

smith?s eyes told Retgar he would get a

higher price here than at any other shop.

They finished their transaction, and

Retgar stepped back into the busy street,

tucking his now-full purse beneath his tunic.

He had one more stop to make outside

of town, and he wanted to hurry because

the sun would be setting soon.

The value of most silver items was in the

silver itself, so items were often melted

down and recrafted. A whitesmith (one who

works any metal other than iron) could

normally work with any of the precious

metals but would usually concentrate on

one. Smiths often would specialize in chasing,

engraving or embossing. A whitesmith

would seldom be found outside a city.

Items of interest for game purposes: small

hammers (most under ½ lb.), acid (one vial

will do one point of damage to exposed flesh

or will corrode cloth and similar materials),

charcoal (improvised blackface; S), soot (S),

powdered brass (S), powdered silver (S),

brazier (S), small engraving tools (might

double as crude thieves? tools), shovel, longhandled

dipper (useful for testing unknown

liquids at arm?s length), scraps or sheets of

precious metals, and finished items. Some

specific spell components that can be manufactured

by a silversmith include; a small

silver horn, a tiny silver whistle, a small

silver rod, and a miniature platinum sword.

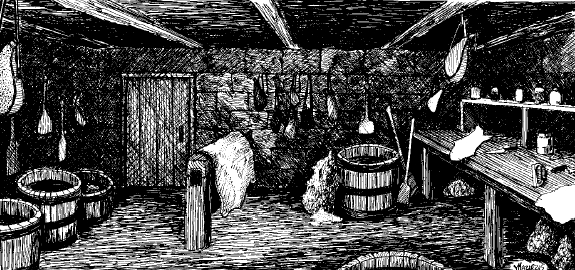

The tanner's hide

Retgar stepped easily from stone to stone

as he crossed the stream. Plants growing at

the water?s edge dangled their brown, withered

leaves in its bubbling surface, which

was poisoned by tanning wastes from up-

stream. He paused long enough to assure

himself that no surprises awaited him at the

grey stone building cradled in the side of the

hill. The skins and hides stretched on

frames beside the door revealed this as the

home of Sandler the tanner. The salted

hides had been brought out from the back

room deep within the hillside, where they

had been stored since last fall. As Retgar

pushed open the low wooden door, a cool

rush of air assaulted his face, bearing with it

an overpowering smell of leather and vinegar.

After crossing the threshold, he waited

for his eyes to adjust to the dimness.

The tanner was nowhere to be seen, but

Retgar knew he wouldn?t be far away. Then

he heard the sounds of movement outside

the shop, and realized that Sandler was

nearby. Keeping one eye on the outside

door, Retgar moved around the interior of

the room and took note of what he saw.

Scattered around the room were barrels

and tubs of tanning solutions. Some hides

were soaked for months, being shifted to

progressively stronger solutions until the

process was complete. Retgar crossed to the

long table at one end of the room. He poked

around curiously at the strangely shaped

knives with his dagger. Most were toothed

or had dulled edges to avoid cutting the

hide when scraping off hair or flesh. Some

were even made of wood for more tender

skins like those of rabbits. Above the table

was a shelf of jars holding crushed herbs to

dye the leather. On the floor at the far end

of the table was a barrel of vinegar, a neutralizer

for the lime used to remove hair.

Salt spilled on the dirt floor from a large

sack propped against the vinegar.

Picking up one of many long-handled

stirring paddles, Retgar raised a piece of

leather from the tannic acid and let it slip

back into the dark bath. Turning, he

brushed against a group of leather flasks

hanging on the wall. He didn?t need to

uncork them to know that at least one of the

flasks held fish oil used to waterproof

leather. Undoubtedly there were other oils

in the remaining skins that were less aromatic.

Stepping around the smooth horizontal

beam over which leather was draped

while being worked, he pushed open the

door to the back room. The air was cool

and heavy with the stench of salt-cured

hides that had been stored here awaiting

tanning. Retgar slipped inside, closed the

door, and glanced quickly about the room.

Just then, the sound of approaching horses

caused Retgar to flatten against the wall

and strain his ears to catch any conversation

from outside. He heard enough to know

that the troops were employed by Zagus,

and they were questioning Sandler the

tanner to find out if he had seen Retgar

traveling toward the city. In fact, Retgar

had entered the city and already left it; by

arriving in the area one day earlier than he

had been expected to, Retgar had helped to

insure his own continued safety.

When the sound of the men and horses

had again faded into the distance, the tanner

came inside and resumed working on

the leather hung over the wooden beam.

Retgar slipped out of the back room, silently

stepped up behind Sandler, and

pressed his dagger against the tanner?s

throat. He whispered, ?You would have

sold me to Zagus just as if I were one of

your skins. But now, I want the bulette hide

that you have concealed here. I paid for that

hide with my own blood ? and unless you

want the captain of the guard to find you

stretched and curing on one of your own

racks, I suggest you. deliver what is mine.?

?Zagus will be most displeased,? said the

tanner weakly.

"His emotions are not my concern,?

growled Retgar. ?I can guarantee your fate

if you do not do as I tell you.?

A little more pressure with the sharpened

steel soon had the tanner outside digging

through the pile of leaves and bark he had

collected to make tannic acid. He finally

unearthed a package wrapped in leather. As

Retgar opened the bundle, the grayish-blue

scales glistened in the now fading sunlight.

?The workmanship is as fine as you had

promised, although the service is less than

desirable. Since I am a man of honor, unlike

some of those you deal with, here is the

payment I promised,? said Retgar.

He tossed a bag of coins at the tanner?s

feet, turned, and was soon lost in the growing

darkness. He was one step closer to an

armored vest that would be the envy of

every other adventurer he knew ? and he

was still one step ahead of the revenge of

Zagus.

.

.

.

.

.

Tanneries are located near water and

outside of town due to the foul odors they

produce. A cool storage area is usually

necessary to hold skins until a sufficient

quantity is obtained to begin tanning.

Items of interest for game purposes:

coarse salt (application to an open wound

loosens a prisoner?s tongue; S), barrels,

brushes, fish oil (masks scents), other oils

and fats (good base for ointments), dyes

(can darken or lighten hair or skin; S),

beeswax (good lubricant), vinegar (astringent),

lime (helps neutralize acids; S),

knives (only a few useful as weapons), tannic

acid (not strong enough to do damage,

but will discolor skin), pitch (S), grain

alcohol (S), bark chips (S), and pieces of

uncut leather and skins.

.

.

.

.

.

.

The preceding descriptions are intended

as a guide for fleshing out similar shops in

your campaign. Each establishment is

unique and reflects not only its political,

cultural, and economic environment, but

also the tastes and habits of the owner.

The services offered by a craftsman need

not be handed to player characters on a

silver platter. Shopping can be as much an

adventure as any other part of a campaign

JUNE 1985